Mini-ITX board in ATX Case: Engineer’s Deep Dive & Deployment

Table of Contents

- Introduction

- Form Factor Standards Overview

- Mechanical Integration

- Power and Electrical Considerations

- Thermal Design and Airflow

- Functional and Operational Advantages

- Industrial and Embedded Applications

- Aesthetic Design and Case Utilization

- Acoustic Dynamics in Large Cases

- Build Workflow and Future Flexibility

- Mechanical Risks and Mitigation

- Cost and Supply Chain Considerations

- Best Practices and Recommendations

- Future Trends

- Conclusion

- References and Further Reading

Introduction

Deploying a Mini-ITX motherboard inside an ATX chassis is a strategic choice embraced by professionals who want to leverage compact computing while gaining the mechanical and thermal benefits of full-size enclosures. This combination is frequently seen in industrial control systems, quiet workstation builds, and scenarios requiring scalable power delivery. This guide offers comprehensive insights on mechanical fitment, airflow strategies, power considerations, and design trade-offs to help hardware engineers and embedded system integrators plan reliable, maintainable systems.

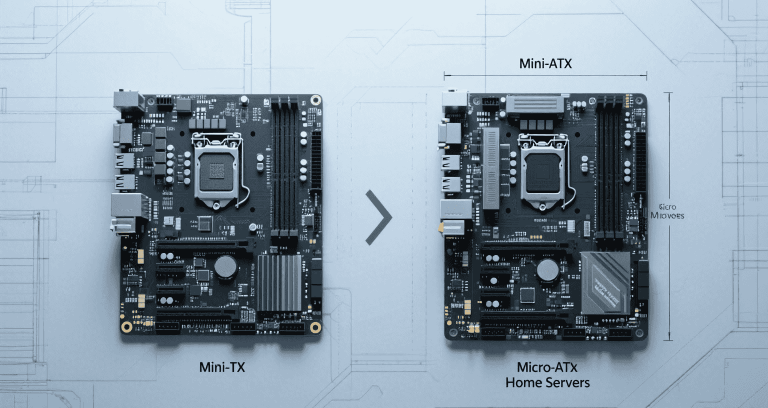

Form Factor Standards Overview

Understanding the fundamental size, mounting, and I/O specifications of ATX and Mini-ITX is critical before you start your integration project. This section describes the standards that impact mechanical alignment and component compatibility.

ATX Form Factor Dimensions

ATX is the most established motherboard standard for desktops and workstations. It offers extensive expansion capability and generous component spacing.

| Attribute | Specification |

|---|---|

| Width | 305 mm |

| Depth | 244 mm |

| Mounting Holes | 9 positions |

| Expansion Slots | Up to 7 PCIe slots |

| I/O Shield | Standard ATX size (99 mm × 44 mm) |

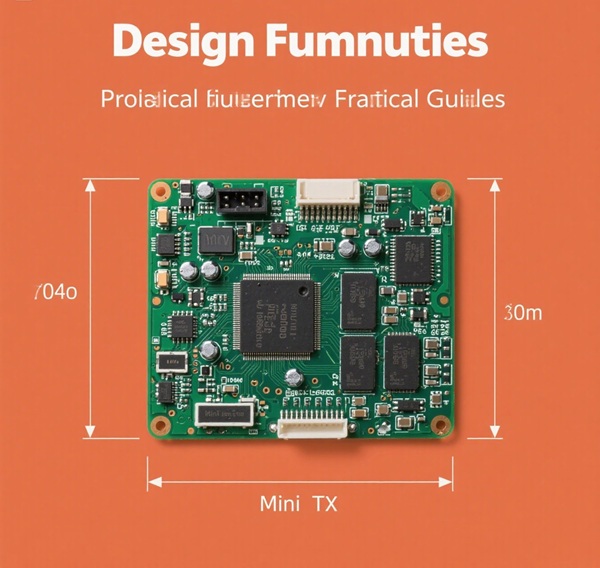

Mini-ITX Form Factor Dimensions

Mini-ITX is popular for compact builds due to its small footprint and efficient layout.

| Attribute | Specification |

|---|---|

| Width | 170 mm |

| Depth | 170 mm |

| Mounting Holes | 4 positions |

| Expansion Slots | 1 PCIe x16 slot |

The rear I/O shield dimensions remain consistent with ATX, simplifying integration.

Mechanical Integration

Proper mechanical fitment ensures stability, prevents electrical shorts, and allows clean cable routing. This section explains best practices and precautions.

Standoff and Mounting Compatibility

Common Standoff Positions Supporting Mini-ITX

Most ATX trays include labeled standoff positions compatible with Mini-ITX. Always cross-check case documentation or reference stamping labels.

Unused Standoffs and Grounding Precautions

Leaving extra standoffs in place can cause shorts. Remove any unaligned standoffs or cover them with insulating washers.

ATX Tray Compatibility with Mini-ITX I/O Shield

Mini-ITX shields snap into the standard ATX I/O cutout without adapters, simplifying installation.

Expansion Slot Alignment

The single PCIe slot of a Mini-ITX board aligns to the top slot of an ATX backplane. Remaining slots remain unused and can be covered with blanking plates to improve aesthetics and airflow.

Cable Length and Routing Implications

Using an ATX chassis often results in excess cable length. Modular PSUs and careful bundling are essential to avoid airflow obstruction and cable damage.

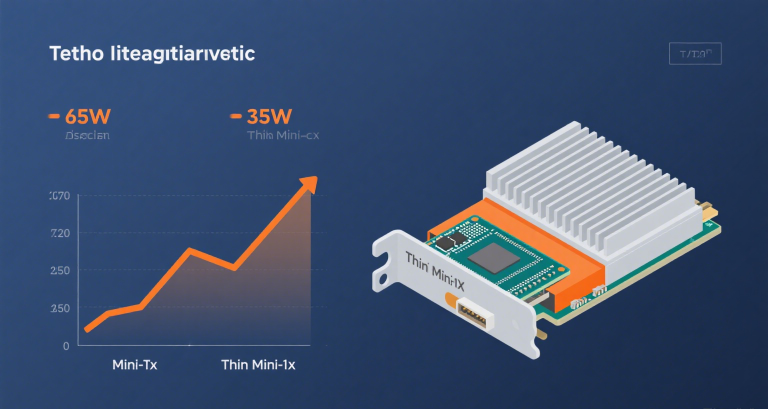

Power and Electrical Considerations

Power design is crucial when deploying Mini-ITX in a larger case. You must account for efficiency, cable management, and power distribution.

PSU Form Factor Selection

ATX PSUs are standard, but SFX units can be beneficial for reducing clutter. SFX-to-ATX adapter brackets are inexpensive and widely available.

Power Consumption Profiles

| Scenario | Approximate Power Draw |

|---|---|

| Basic Embedded Control Build | 30–80W |

| Ryzen 7 + Discrete GPU | 150–250W |

| Idle Low Load | 20–50W |

Be aware that high-capacity PSUs are less efficient below 20% load.

Auxiliary Power Requirements

High-performance GPUs require additional PCIe power cables. Also consider SATA power distribution for multiple drives and fan hubs.

Thermal Design and Airflow

Thermal performance is a major advantage of full-size cases. However, planning is needed to avoid dead zones and overcooling.

Airflow Patterns in Larger Enclosures

ATX cases use front-to-back or bottom-to-top airflow. In a build with a Mini-ITX board, dead zones can form around empty areas. Consider adding intake fans with wide dispersion patterns.

CPU Cooler Compatibility

Large enclosures accommodate tall tower coolers (up to 180mm) or AIO radiators (240/280mm), providing significant thermal headroom.

Overcooling Risks and Mitigation

Low-load systems with excessive airflow can create noise and turbulence. Tune fan curves to maintain a balance between cooling and acoustics.

Functional and Operational Advantages

Pairing Mini-ITX with ATX cases brings unique benefits beyond airflow and power headroom.

Enhanced Expansion Options

- Full-size GPUs for AI workloads or simulation

- Dedicated capture cards or network cards

- Extra drive bays for RAID configurations

Improved Serviceability

Spacious cases make cable management and component access easier. This is particularly valuable for embedded or industrial deployments requiring frequent service.

Noise Reduction Opportunities

Larger fans can spin more slowly, reducing acoustic footprint. Vibration isolation becomes more effective with more mass and room.

Industrial and Embedded Applications

Mini-ITX boards in ATX cases are common in rugged, high-reliability systems.

Use Cases in Industrial Computing

Fanless embedded builds are often installed in ATX enclosures to dissipate heat passively and protect components from dust.

Integration in OEM and Custom Builds

Large chassis allow space for custom I/O backplanes, specialized connectors, or redundant power supplies.

Aesthetic Design and Case Utilization

This section explores strategies to make your build visually balanced and professional.

Managing Empty Spaces

- Install blank plates or shrouds

- Add RGB lighting for accent

- Use empty bays for extra storage

Visual Balance in Case Layout

Center the motherboard visually and route cables cleanly to maintain symmetry and appeal.

Acoustic Dynamics in Large Cases

Acoustic optimization is easier in spacious enclosures.

Resonant Zones and Frequency Peaks

Use foam mats and grommets to damp low-frequency hum from panels and drives.

Quiet Operation for Low-Load Systems

Careful fan selection and curve tuning ensure near-silent operation at idle.

Build Workflow and Future Flexibility

Planning ahead allows easier upgrades and maintenance.

Assembly Best Practices

- Confirm standoff alignment

- Use torque-limited screwdrivers

- Label every cable

Planning for Future Mini-Case Upgrades

Modular PSU cables and universal mounts make migrating easier.

Mechanical Risks and Mitigation

This section addresses common installation hazards.

Mechanical Stress and Mounting Precautions

Support the board while connecting cables to prevent flex and microfractures.

EMI and Signal Integrity

Route data cables separately from power cables and use shielding where necessary.

Cost and Supply Chain Considerations

Understand the budget and procurement trade-offs of this approach.

Price Implications

- Reuse ATX cases to reduce cost

- Budget for fillers and adapters

Accessory and Spare Part Availability

Stock spare I/O shields, standoff kits, and extension cables for long-term support.

Best Practices and Recommendations

Follow this checklist for a successful build:

- Verify mechanical fitment before assembly

- Plan airflow zones and cable routing

- Label everything for serviceability

Future Trends

Stay aware of evolving technologies shaping this integration method.

Mini-ITX Board Evolution

Expect higher power density and PCIe 5.0 GPU support.

ATX Chassis Innovations

Look for modular trays, advanced airflow baffles, and improved cable management.

Conclusion

Pairing a Mini-ITX board with an ATX enclosure delivers compelling advantages but requires deliberate planning. For professional advice and product selection, visit MiniITXBoard.

References and Further Reading

- Intel ATX Specification v2.2

- Mini-ITX Design Guide

- IPC-2221 Standards

- MiniITXBoard Technical Resources