Mini-ITX Boards with 4 RAM Slots: Design Constraints

Table of Contents

- Essential Introduction

- Mini-ITX Form Factor and Memory Constraints

- Market Availability and Rarity of 4-DIMM Mini-ITX Boards

- Mechanical and Electrical Design Considerations

- Memory Configuration and Performance

- BIOS Memory Training and Stability Tuning

- Thermal Management Challenges

- GPU Clearance and DIMM Slot Conflicts

- SODIMM vs UDIMM Compatibility

- Chassis Compatibility and Integration

- Application Scenarios

- Power Delivery and Overclocking Considerations

- Supply Chain Planning and Procurement Risks

- Future Trends and Emerging Technologies

- Cost and BOM Considerations

- Best Practices and Recommendations

- Conclusion

- References and Further Reading

Essential Introduction

High-capacity memory is increasingly essential for embedded platforms, advanced analytics, and edge computing workloads. Traditional Mini-ITX boards offer only two DIMM slots, which can limit the scalability of your applications. Emerging 4-DIMM Mini-ITX boards deliver higher memory ceilings in a compact footprint but require deliberate design choices. This guide equips hardware engineers and embedded system integrators with expert insights into selecting, integrating, and maintaining 4-DIMM Mini-ITX solutions for demanding environments.

Mini-ITX Form Factor and Memory Constraints

Before choosing a board, it’s important to understand why Mini-ITX boards have been traditionally limited in memory expansion and what design trade-offs occur when adding four DIMM slots.

Standard Mini-ITX Footprint

The Mini-ITX specification defines a board size of 170mm × 170mm (6.7″ x 6.7″). This compact footprint leaves limited space for memory slots, VRMs, CPU socket, and connectors.

- 4 mounting holes compatible with ATX/Micro-ATX trays

- Single PCIe x16 slot

- Rear I/O panel matching standard ATX cutouts

Engineering Trade-Offs of 4-DIMM Layouts

To fit four DIMM slots, designers must:

- Use higher-layer PCB stack-ups for routing

- Implement tighter impedance control

- Increase VRM capacity to handle more modules

This increases cost, complexity, and thermal density.

Market Availability and Rarity of 4-DIMM Mini-ITX Boards

Only a few manufacturers offer such boards due to low demand and production complexity.

Overview of Available Platforms

- AMD AM4/AM5 workstation Mini-ITX with 4 UDIMM slots

- Intel LGA1700 Mini-ITX with ECC UDIMM support

- Embedded SODIMM Mini-ITX targeting industrial applications

Sourcing and Lead Time Challenges

Common challenges include:

- OEM-only availability

- Extended lead times (8–16 weeks)

- Short product lifecycles with frequent EOL transitions

Mechanical and Electrical Design Considerations

Mechanical clearance and electrical integrity are primary concerns with 4-DIMM Mini-ITX boards.

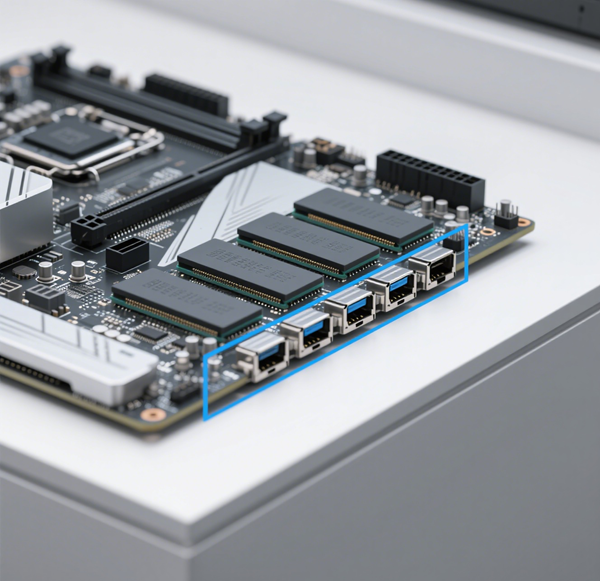

DIMM Socket Placement and Clearance

Adding slots increases proximity to the CPU socket and PCIe slot, requiring careful cooler and GPU selection.

Mechanical Stability Under Load

Fully populated slots increase board flex. Industrial deployments require stiffer trays and vibration damping.

Trace Length and Signal Integrity

Longer trace lengths degrade DDR5 signal quality. Manufacturers often use higher-quality PCB materials to reduce timing errors.

Memory Configuration and Performance

Four DIMM slots do not automatically enable quad-channel bandwidth.

Supported Capacities and Speeds

| Memory Standard | Max Capacity (4 Slots) | Common Speeds |

|---|---|---|

| DDR4 UDIMM | 128GB | 2133–3600MHz |

| DDR5 UDIMM | 192GB+ | 4800–7200MHz |

Dual-Channel vs Quad-Channel Myths

Even with four slots, most CPUs remain dual-channel. Capacity increases, but bandwidth does not double.

ECC and Registered Memory Support

Some models support ECC UDIMMs, beneficial for scientific computing and virtualization workloads.

BIOS Memory Training and Stability Tuning

4-DIMM configurations complicate POST and stability.

Common POST Delays

Memory training may take 60–90 seconds. This is normal behavior and requires patience.

Memory Profile Configuration

- Use XMP/EXPO cautiously

- Consider manual tuning for voltage and timings

Thermal Management Challenges

Dense DIMM banks and more VRMs lead to higher temperatures.

VRM Cooling and Power Delivery

More phases are required to support additional modules. Heatsinks can become saturated without airflow.

Airflow Over Dense DIMM Banks

- Top-down coolers improve memory airflow

- Side intake fans can reduce hot spots

GPU Clearance and DIMM Slot Conflicts

Large GPUs may block DIMM latches or interfere with module clearance.

Compatibility Mapping

Review mechanical drawings to ensure clearance before finalizing parts.

Low-Profile Memory Alternatives

LP UDIMMs or SODIMMs can reduce interference and improve cooling.

SODIMM vs UDIMM Compatibility

Each memory type has unique characteristics.

| Feature | UDIMM | SODIMM |

|---|---|---|

| Form Factor | Full-height | Compact |

| Typical Use | Desktop/server | Mobile/embedded |

Sourcing and Cost Implications

SODIMMs can be harder to source in high capacities and may carry higher premiums.

Chassis Compatibility and Integration

Clearance and cable management are critical in compact enclosures.

CPU Cooler Clearance

- Air coolers often conflict with tall DIMMs

- AIO coolers improve compatibility and airflow

Cable Management Best Practices

Plan EPS and fan cable routing to avoid compressing memory modules.

Application Scenarios

Examples where 4-DIMM Mini-ITX excels:

- Edge computing AI inference nodes

- Industrial data acquisition and logging

- Compact virtualization servers

Power Delivery and Overclocking Considerations

High memory counts increase power draw and heat.

VRM Design for High-Frequency Memory

Boards must use robust VRMs and heat dissipation solutions to maintain stability.

PSU Selection and Headroom

Leave 30% power headroom to accommodate load spikes.

Supply Chain Planning and Procurement Risks

These boards are niche, with sourcing challenges.

Lead Time Challenges

Expect 8–16 week lead times and plan procurement accordingly.

Lifecycle Management

Some models have a 24-month lifecycle; maintain spare inventory.

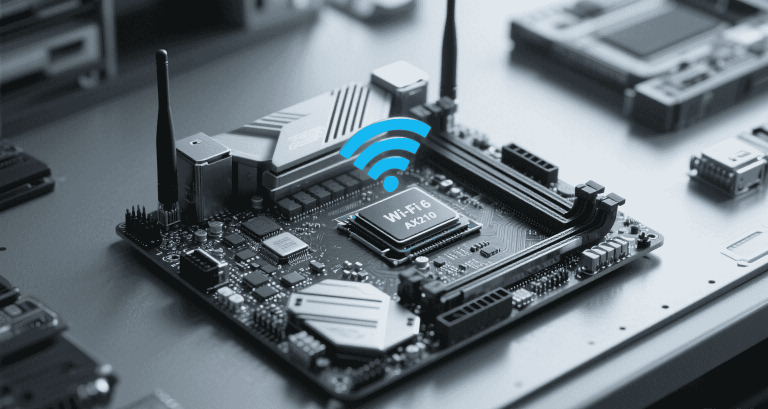

Future Trends and Emerging Technologies

Trends to monitor:

- DDR5 scaling beyond 8000MHz

- Soldered SoC solutions reducing modularity

- Server-grade SODIMM Mini-ITX boards

Cost and BOM Considerations

4-DIMM Mini-ITX boards command premiums.

Pricing Trends

| Feature | Typical Premium |

|---|---|

| 4-DIMM Layout | +20–40% |

| ECC Support | +10–25% |

Strategies to Optimize BOM

- Select only essential features

- Consider SODIMM designs for embedded applications

Best Practices and Recommendations

- Confirm mechanical drawings for compatibility

- Validate BIOS memory training behavior

- Stress test configurations before deployment

Conclusion

4-DIMM Mini-ITX boards unlock new levels of performance for compact systems but demand careful validation, planning, and supply chain management. For design assistance and resources, visit MiniITXBoard.

References and Further Reading

- Mini-ITX official specification documents

- DDR5 JEDEC standards

- Vendor datasheets

- Embedded design guides

- MiniITXBoard Resources