Mini‑ITX Motherboard VRM Design and Quality

Table of Contents

- Introduction

- What is a VRM and Why It’s Critical

- Phase Count, Load Distribution, and PCB Topology

- MOSFETs, Chokes, and Capacitor Selection

- Thermal Design: Heatsinks and Cooling Approaches

- VRM Monitoring and BIOS Integration

- Case Compatibility and VRM Heatsink Oversizing

- Signal Integrity and EMI Risk in Dense Boards

- Long-Term Reliability in Industrial and 24/7 Use

- Budget vs Premium Mini‑ITX VRM Comparison

- Engineering Validation and Testing Techniques

- Deployment Checklist and Best Practices

Introduction

When building high-performance Mini‑ITX systems, the **Voltage Regulator Module (VRM)** is often the critical—but overlooked—determinant of stability. Especially in thermally constrained environments, VRM design affects everything from CPU overclocking to 24/7 embedded uptime.

This article explores Mini‑ITX VRM considerations with a focus on real-world integration challenges, thermal layout trade-offs, component choices, and long-term reliability. Whether you’re designing fanless embedded systems or power-dense desktop builds, the VRM must be a deliberate engineering decision—not an afterthought.

What is a VRM and Why It’s Critical

VRMs regulate 12 V input into lower voltage rails for CPUs (Vcore), SoCs, and memory controllers. In high-current CPUs, power quality is directly tied to VRM efficiency, ripple control, and transient response. For Mini‑ITX systems, these factors are intensified by space, thermal, and routing constraints.

Phase Count, Load Distribution, and PCB Topology

Boards vary by VRM phase configuration:

| Board Type | VRM Phases | Target CPUs |

|---|---|---|

| Entry A520I / H610I | 4+1 | i3 / Ryzen 3–5 |

| Mid X670E‑I / B650I | 6+2 | Ryzen 7 / Intel i5 |

| Flagship Z790‑I | 10+2 | Ryzen 9 / Intel i9 |

Higher phase count reduces per-phase heat and improves voltage regulation. However, more phases require complex routing, often constrained in Mini‑ITX PCBs with only 4–6 layers.

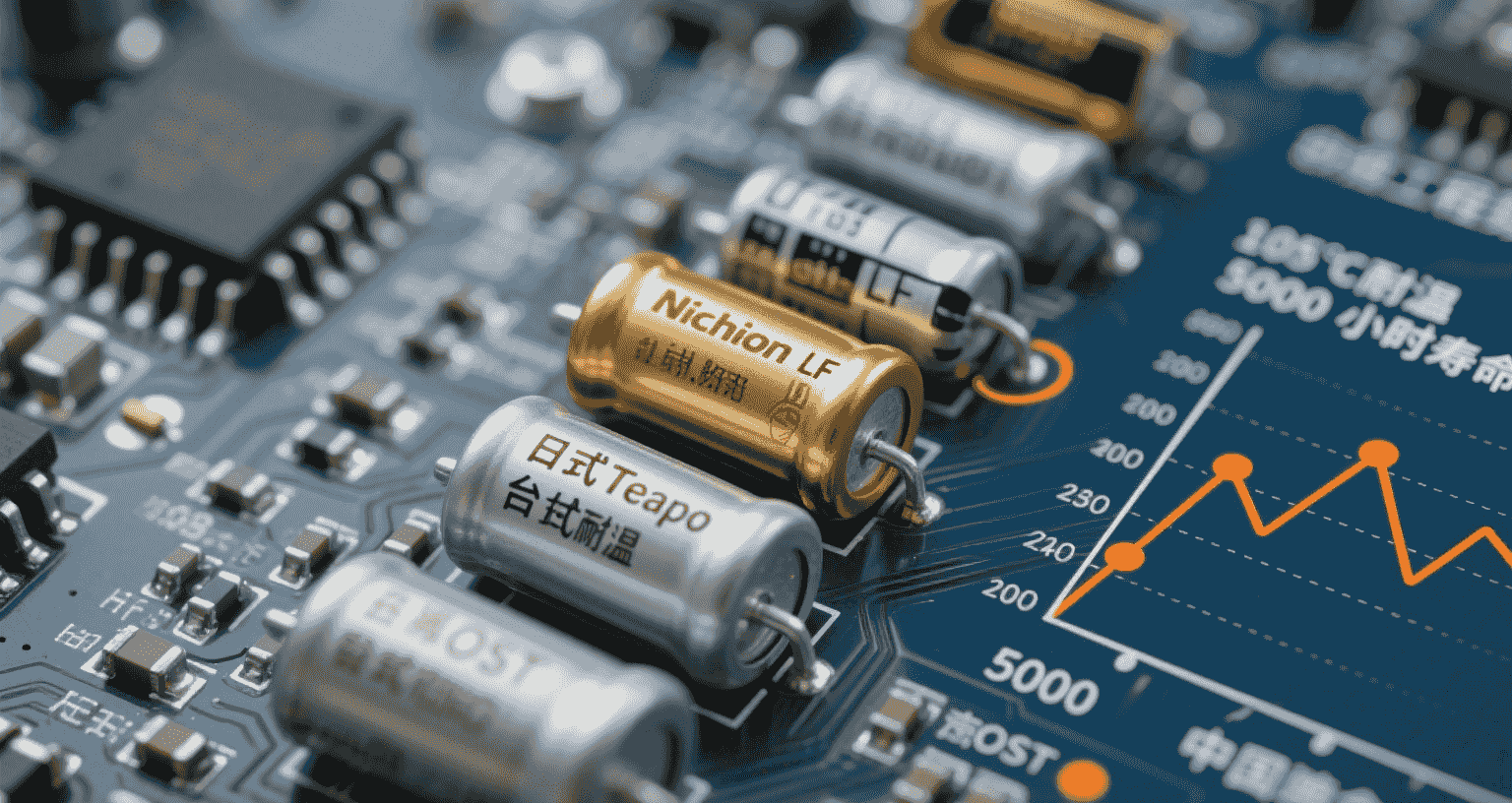

MOSFETs, Chokes, and Capacitor Selection

High-quality VRMs use:

- DrMOS stages rated ≥50 A continuous

- Polymer or ceramic capacitors (105 °C or above)

- High-inductance ferrite chokes for clean output

“Capacitor degradation in ITX VRMs was the root cause of two thermal shutdowns we investigated in our field systems.” — Integrator Note

Thermal Design: Heatsinks and Cooling Approaches

Heatsink choice dramatically affects VRM lifespan. Budget boards use thin aluminum or simple extrusions, while premium boards add:

- Heatpipes connecting VRM to I/O shield

- Micro-fin copper layers or embedded VRM fans

Community tests confirm some Mini‑ITX boards exceed 100 °C VRM temps without airflow—especially under synthetic load.

VRM Monitoring and BIOS Integration

Good boards expose VRM data via:

- Dedicated thermal sensors (visible in BIOS or HWInfo)

- Load-line calibration (LLC) levels

- Fan response curves mapped to VRM zones

Lower-end boards often lack monitoring, forcing engineers to estimate thermal conditions via external IR tools.

Case Compatibility and VRM Heatsink Oversizing

Oversized VRM heatsinks may block:

- CPU cooler brackets

- Top-mounted fans

- Front-panel wiring space

Boards like the MSI B650I Edge include aggressive shrouds that clash with many SFF enclosures—requiring cable rerouting or fan removal.

Signal Integrity and EMI Risk in Dense Boards

Mini‑ITX designs often place high-speed lanes (PCIe, USB4) adjacent to VRMs. Without shielding and ground isolation, engineers report issues such as:

- USB dropouts

- Wi‑Fi interference

- Sensor signal errors

“Our inferencing edge node failed QA due to cross-talk between switching VRMs and CSI camera bus.” — Embedded Design Lead

Long-Term Reliability in Industrial and 24/7 Use

Fanless or 24/7 systems must consider derating VRMs by 10–20% for longevity. Additional recommendations:

- Use boards with polymer caps and thermal pads

- Log VRM temps during peak compute loads

- Specify airflow ducts or aluminum backing in passive enclosures

Budget vs Premium Mini‑ITX VRM Comparison

| Feature | Budget ITX | Premium ITX |

|---|---|---|

| Phases | 4–5 | 8–12 |

| MOSFETs | Discrete (≤40 A) | Smart Power Stage (≥60–100 A) |

| Cooling | Basic passive | Heatpipe + fin array |

| Sensor Support | None or limited | Full VRM telemetry |

| Fan Headers | 1–2 | 3–4 + VRM fan header |

Engineering Validation and Testing Techniques

- Run 1‑hr all-core loads (e.g. Cinebench R23 loop)

- Use FLIR thermal imaging to inspect VRM zones

- Measure ripple via oscilloscope: aim for ≤50 mV under load

Ideal VRM zones should stay below 80–85 °C in ventilated Mini‑ITX setups.

Deployment Checklist and Best Practices

- ✅ Match VRM design to CPU TDP

- ✅ Ensure directed airflow over VRMs

- ✅ Avoid boards with poor VRM sensor visibility

- ✅ Confirm case clearance around VRM sinks

- ✅ Test cold boot, sustained load, and thermal response

Target System:

Ryzen 9 7900X

→ TDP: 105 W (peak ~150 W)

Recommended: 8+2 phase, 60 A DrMOS, copper heatsinks

Case: Meshlicious or NR200

PSU: 650 W SFX GoldBy prioritizing VRM quality and thermal design, hardware engineers can ensure long-term reliability—even in tightly packed Mini‑ITX systems. Boards from trusted brands with strong community validation help avoid surprises in thermally aggressive deployments.