Micro ATX Board in Mini ITX Case: Compatibility, Limitations

Table of Contents

Introduction

As embedded system designers and hardware engineers, you’re often expected to deliver high-performance solutions in space-constrained environments. Occasionally, you may consider unconventional combinations—such as using a Micro-ATX motherboard inside a Mini-ITX enclosure—to save costs or leverage existing parts. However, this approach can introduce significant mechanical, thermal, and electrical challenges that jeopardize reliability and maintainability.

Form Factor Dimensions and Standards

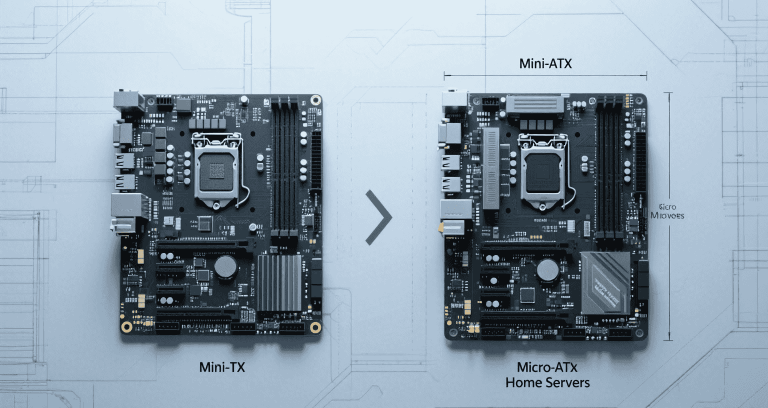

This section explains the physical and mechanical specifications that define Micro-ATX and Mini-ITX motherboards. Understanding these dimensions is essential before you attempt any cross-form-factor installation.

Micro-ATX Overview

| Parameter | Micro-ATX Specification |

|---|---|

| Dimensions | 244 × 244 mm |

| Mounting Holes | 8 positions |

| PCIe Slots | Up to 4 |

Mini-ITX Overview

| Parameter | Mini-ITX Specification |

|---|---|

| Dimensions | 170 × 170 mm |

| Mounting Holes | 4 positions |

| PCIe Slots | 1 (x16) |

Mechanical Incompatibility Summary

Physically, a Micro-ATX board will overhang by 74 mm per side in a Mini-ITX case, misaligning standoffs and PCIe slot locations. This makes conventional mounting impossible without heavy modification.

Electrical and Power Connector Compatibility

In this section, I’ll walk you through how power connectors, VRMs, and power delivery differ between Micro-ATX and Mini-ITX designs, and why these differences matter in confined enclosures.

ATX Power Connector Locations

Micro-ATX boards place the 24-pin connector further to the right, often near the middle of the board, and the CPU EPS connector at the top edge. Mini-ITX cases assume these connectors are closer together.

Implications for Cable Management

- Short PSU cables may not reach connectors

- Excessive bending stress on wires

- Potential for intermittent connections

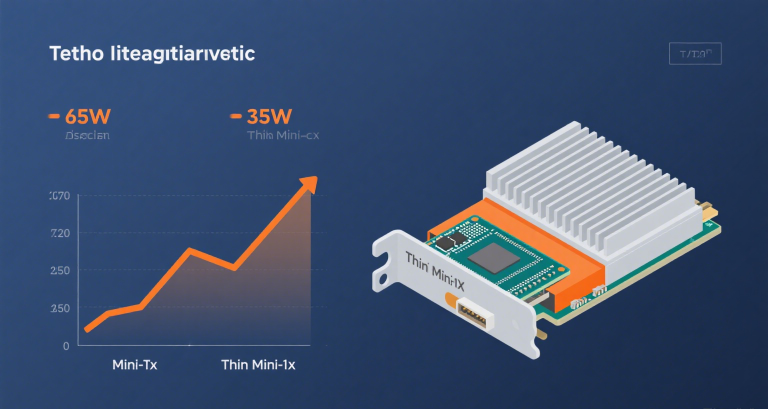

VRM and TDP Support Comparison

| Board Type | Typical TDP Support |

|---|---|

| Mini-ITX | 65–95 W |

| Micro-ATX | 95–150 W |

Thermal Design and Heat Dissipation

This section focuses on how airflow, CPU cooling, and GPU thermal loads interact with form factor constraints, which is often the main reason such builds fail in production.

CPU Cooler Constraints

Most Mini-ITX cases have CPU cooler clearances below 60 mm. Micro-ATX motherboards assume you can fit taller tower coolers (~120 mm).

Real-World Example

“We tested a 95W CPU in a Mini-ITX chassis with a 37 mm cooler and saw sustained thermal throttling at 85°C.” — Senior Thermal Engineer, MiniITXBoard

GPU and Expansion Card Airflow

Limited internal volume restricts exhaust pathways. High-power GPUs can quickly saturate internal air, increasing the risk of VRM overheating.

Expansion Slot and I/O Scalability Comparison

In this part, I compare the expansion capabilities of Micro-ATX versus Mini-ITX, including PCIe, M.2, and networking options, and explain the practical consequences of mismatched configurations.

Expansion Slot Comparison

| Feature | Mini-ITX | Micro-ATX |

|---|---|---|

| PCIe Slots | 1 x16 | Up to 4 |

| M.2 Slots | 1–2 | 2–3 |

Implications

Even if you install a Micro-ATX board, the Mini-ITX case physically blocks additional slots, negating any expandability gains.

Rear I/O Port Layout Considerations

Here, you’ll learn how I/O shield alignment and rear port accessibility impact installation and maintenance when combining Micro-ATX boards with Mini-ITX enclosures.

I/O Shield Alignment

Mini-ITX enclosures expect a 170 mm-wide I/O area, causing misalignment:

- Partial obstruction of ports

- Mechanical stress on connectors

- Inability to secure the I/O shield

USB and Video Port Conflicts

Internal brackets and fans can block or partially cover ports, compromising usability and signal integrity.

Assembly and Maintenance Factors

This section covers practical issues such as cable management, component replacement, and how constrained space affects serviceability and reliability over time.

Cable Management Limitations

Mini-ITX cases have few tie-down points. Extra cables from a larger board can clog airflow paths.

Component Replacement Difficulty

- PSU often must be removed first

- High risk of damaging connectors

Cost and Procurement Considerations

Here, I’ll help you assess whether mixing form factors actually saves money when you factor in extra labor, cooling solutions, and potential rework costs.

Motherboard and Case Cost Comparison

| Item | Mini-ITX | Micro-ATX |

|---|---|---|

| Motherboard Cost | Higher per feature | Lower per feature |

| Case Cost | Higher per liter | More options |

Total Cost of Ownership

Custom harnesses, additional cooling, and longer assembly time often erase any upfront savings.

Compatibility Validation and Verification Process

This part details a structured approach to verifying mechanical fit and thermal performance before committing to production builds, helping you avoid expensive mistakes.

Mechanical CAD Workflow

- Import 3D models of the board and case

- Verify standoff alignment

- Check clearance envelopes

- Simulate airflow

- Plan cable routing

Pilot Builds and Testing

Prototype assembly is strongly recommended to confirm fit and validate thermal performance under load.

Regulatory and Industry Standards

In this section, I outline certifications, environmental regulations, and testing standards that apply to embedded systems using mixed form factors.

Certifications

- CE

- FCC Class B

- RoHS/REACH

Industrial Requirements

- Vibration: IEC 60068-2-6

- Shock: IEC 60068-2-27

- Temperature cycling: –20 to +70 °C

Special Exceptions and Hybrid Cases

Here, I share examples of cases and designs that intentionally support both form factors, offering more flexibility if you must combine Micro-ATX boards with compact enclosures.

Dual Compatibility Cases

Certain chassis have adjustable standoffs and backplates to fit multiple form factors.

Example Model

Fractal Design Node 804 supports both Mini-ITX and Micro-ATX.

Alternatives and Solutions

This section provides professional recommendations on choosing the right case or motherboard to achieve your goals without compromising performance or reliability.

Using a Micro-ATX Case

- SilverStone Sugo SG10

- Thermaltake Core V21

Selecting a Mini-ITX Board Instead

| Feature | Mini-ITX | Micro-ATX |

|---|---|---|

| Expansion Slots | 1 | 4 |

| VRM Cooling | Limited | Better |

Summary and Recommendations

Mounting a Micro-ATX board in a Mini-ITX case is generally impractical due to mechanical, thermal, and electrical challenges.

“Always validate compatibility through CAD models and thermal simulation. Mismatched components rarely yield professional-grade reliability.” — Systems Architect, MiniITXBoard

For expert guidance and suitable components, visit MiniITXBoard.