How Real Engineers Build with Miniitxboard

Explore by What Matters to You

Not every project starts the same—and neither do our solutions. Find case studies that match your environment, industry, or technical challenge.

By Industry

- Industrial Automation

- Medical Devices

- Smart Infrastructure

- AI & Vision Systems

- Transportation / Rail

- Retail / Digital Signage

By Deployment Type

- Fanless & Silent

- Harsh Outdoor

- Mobile & Vibration-Resistant

- Cleanroom / Dust-Free

- 24/7 High Uptime

- Compact / VESA-Mount

By Core Technology

- Intel Atom / Core / Xeon

- AMD Ryzen Embedded

- NVIDIA Jetson Series

- NXP i.MX8M / ARM Cortex-A

- Dual-NIC / COM-heavy boards

- Fanless / rugged builds

Enhancing Diagnostic Equipment in the UK

A leading medical diagnostics company in the United Kingdom

- Challenge: The client required a compact, fanless computing solution to integrate into their new line of portable diagnostic devices, ensuring silent operation and compliance with stringent medical standards.

- Solution: We provided a mini PCBA board equipped with an Intel® Atom™ processor, multiple USB ports for peripheral connectivity, and a wide operating temperature range. The board’s small form factor and low power consumption made it ideal for portable medical equipment.

- Result: The integration led to a 25% reduction in device size and a 15% improvement in energy efficiency. The client successfully launched their new diagnostic devices across hospitals in the UK, receiving positive feedback for the equipment’s reliability and performance.

Technologies Used: Intel® Atom™ Processor, USB 3.0, Fanless Design

Modernizing Train Control Systems in Germany

A major railway operator in Germany

- Challenge: The operator needed to upgrade their train control systems to improve safety and efficiency. The new system required a robust computing platform capable of withstanding vibrations and temperature variations inherent in train operations.

- Solution: Our team supplied a rugged mini PCBA board featuring an AMD Ryzen™ Embedded processor, dual Ethernet ports for network redundancy, and extended temperature tolerance. The board’s durability and performance met the rigorous demands of railway applications.

- Result: Post-deployment, the railway operator reported a 30% improvement in system responsiveness and a significant reduction in maintenance downtime. The upgraded control systems enhanced overall operational safety and efficiency across their fleet.operational safety and efficiency across their fleet.

Technologies Used: AMD Ryzen™ Embedded Processor, Dual Ethernet, Extended Temperature Range

Have a Use Case That Sounds Familiar? Let’s Build It

Whether you’re building an edge AI kiosk, automating a factory line, or upgrading transit systems—we’ve probably helped someone solve a similar problem. Share your challenge, and we’ll help you spec the right board, ports, and power profile.

- Custom board configurations (BIOS, layout, I/O)

- Small MOQ options for field testing

- Deployment-ready solutions across EU/US/CA regions

- Industrial-grade quality with full documentation

Implementing Smart Retail Solutions in the USA

A nationwide retail chain in the United States

- Challenge: The retailer aimed to enhance customer experience by deploying interactive kiosks capable of providing product information and personalized recommendations. The solution required a compact, high-performance computing platform with advanced graphics capabilities.

- Solution: We delivered a mini PCBA board powered by an NVIDIA® Jetson™ module, supporting AI-driven applications and high-resolution displays. The board’s compact size allowed seamless integration into sleek kiosk designs.

- Result: The interactive kiosks led to a 20% increase in customer engagement and a 10% boost in sales of promoted products. The retailer plans to expand the deployment to additional stores nationwide.

Technologies Used: NVIDIA® Jetson™ Module, AI Processing, HDMI Output

Deploying Environmental Monitoring Systems in Canada

A Canadian environmental agency

- Challenge: The agency required a reliable, low-power computing solution for remote environmental monitoring stations in harsh climates. The system needed to operate autonomously with solar power and withstand extreme temperatures.

- Solution: We provided a mini PCBA board featuring an NXP i.MX8M processor, multiple I/O interfaces for sensor integration, and ultra-low power consumption. The board’s rugged design ensured dependable operation in remote locations.

- Result: The monitoring stations have been operational for over a year, providing real-time data on environmental conditions with minimal maintenance. The agency has improved its data collection capabilities, aiding in environmental protection efforts.

Technologies Used: NXP i.MX8M Processor, Multiple I/O Interfaces, Low Power Consumption

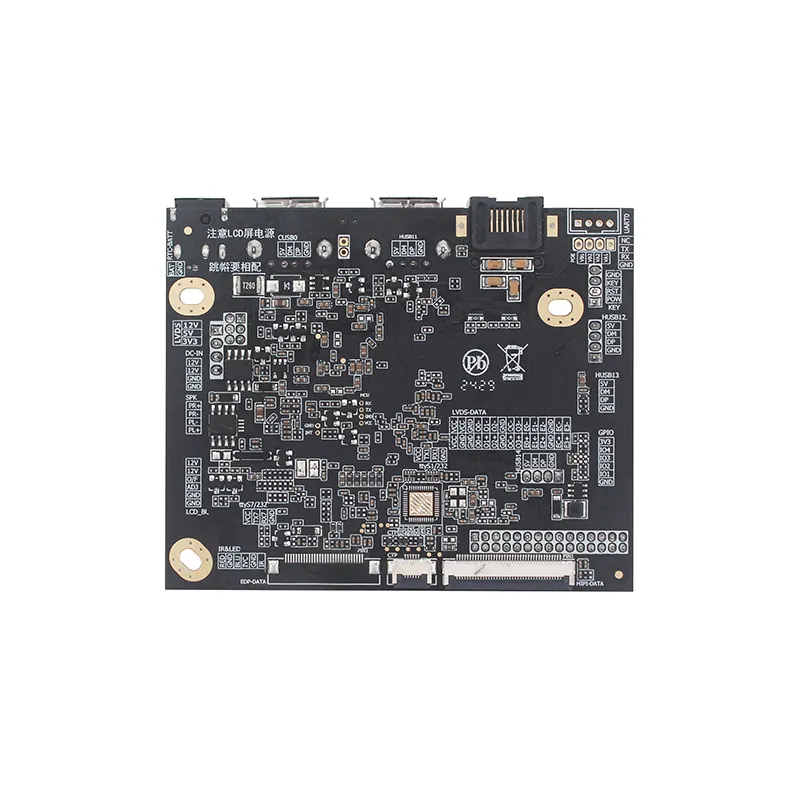

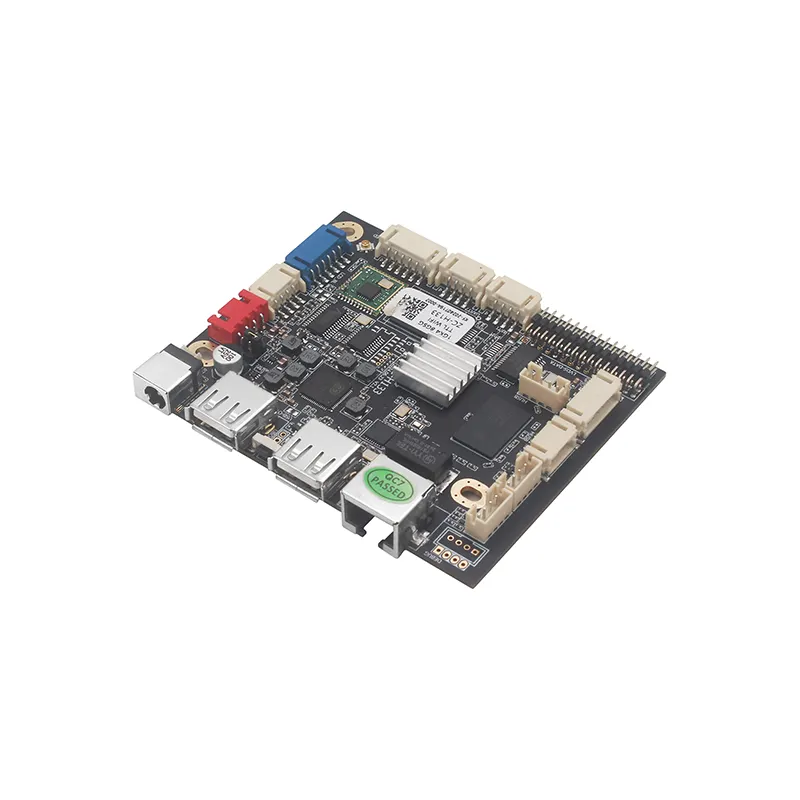

Engineering Detail That Drives Results

Every port placement, connector angle, and signal trace on our Mini-PCBA boards is built to solve real installation problems. In smart devices across Europe and North America, our engineering choices make systems work faster, run cooler, and fit tighter.

Clean USB Signal, Even at High Density

Our USB layout reduces signal crosstalk—even when you run six ports side by side. That means clearer, more reliable connections for SSDs, barcode scanners, and cameras in noisy industrial environments.

Fit-to-Case Port Alignment

We don’t just add ports—we make sure they land in the right place. Our boards support vertical, angled, or low-profile USB headers, so you never have to rework a chassis or use adapters.

Steady, Protected USB Power

Each port delivers stable 5V output with per-port fusing. This helps prevent resets or damage when peripherals spike or stall. From kiosks to medical devices, that means fewer failures in the field.

2×2 Engineering Proof Grid

Tested by Real Installs. Trusted by Real Engineers

At miniitxboard, our USB layouts and system architecture are validated by thousands of real-world deployments—across medical labs, kiosk fleets, factory systems, and more. From signal reliability to thermal stress, our boards are built for conditions where failure isn’t an option.

Runs cool without a fan

Our boards use flat copper zones and layout-based heat spread to avoid hotspots — perfect for sealed boxes and silent systems that can’t rely on airflow.

No more case mods

Headers, I/O, and mount points are planned around your actual device constraints — saving integrators time and avoiding costly chassis redesigns.

No shutdowns, no surprises.

From rail-powered displays to wide-input signage, we validate power delivery across variable voltages and high-draw components — so your system runs clean under load.

Predictable, reliable, repeatable

Each board supports long-lifecycle parts, locked firmware builds, and tailored BIOS — ideal for certifications, compliance, and scaling across deployments.

Want to Know How These Solutions Were Engineered?

Every board spec and layout choice in our case studies started with a design challenge. Dive into the thinking, testing, and hardware strategy that made those real-world results possible. Our blog turns field results into lessons for engineers, integrators, and product teams.

Intel Celeron N150: Balancing Power, Performance, and Practical Efficiency in Compact Systems

Table of Contents 1. Introduction: The Role of the N150 in Modern Embedded Platforms 2. CPU Microarchitecture and Platform Integration 3. Thermal Design and Power Consumption in Real Deployments 4.…

Intel Celeron N300: Engineering Low-Power Performance for Modern Embedded Systems

Table of Contents Introduction: The N300’s Place in Embedded and SFF Markets Architecture & SoC Integration Power Consumption & Idle Realities BIOS & Tuning for Sustained Performance Thermal Performance &…